Diagram Describes the Recycling Process of Aluminum Cans IELTS Task 1

You should spend about 20 minutes on this task.

The diagram describes the recycling process of aluminum cans.

Write at least 150 words.

Real IELTS Exam Question, Reported On:

Practice with Expert IELTS Tutors Online

Apply Code "IELTSXPRESS20" To Get 20% off on IELTS Mock Test

| India | 16th July 2022 |

The Diagram Describes the Recycling Process of Aluminum Cans IELTS Process Diagram

Sample Answer 1

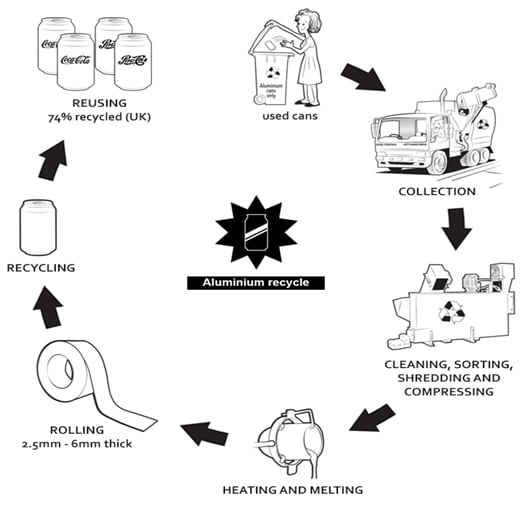

The diagram illustrates how aluminium cans are recycled. First, the cans need to be taken to special collection centres instead of being thrown away with the normal refuse. The cans are collected from here and taken to a factory where they are first sorted and then cleaned. Next, the cans are shredded and crushed in a special machine.

The metal is then heated to a high enough temperature to allow the aluminium to melt. It is then rolled out flat to a thickness of between 2.5mm and 6 mm, depending on what it is going to be used for. The aluminium is now ready to be recycled into new packaging, such as drink containers.

Finally, the new cans are delivered to a soft drinks factory where they are filled. The cans can now be sold to the public and reused. In the UK, 74 per cent of all aluminium cans that are sold are recycled. IELTSXpress

The Diagram Describes the Recycling Process of Aluminum Cans

Sample Answer 2

The diagram presents the recycling process of aluminum. Overall, there are seven stages, starting from throwing used cans and culminating in the reuse of them infamous brands, such as Coca Cola and Pepsi Cola. ieltsxpress

As can be seen clearly, first, people should throw the cans that have been already used, in specific bins, for aluminum only. Secondly, cans are collected and cleaned. After that, drink containers are sorted out, shred and then compressed. In the subsequent stage, the compressed cans are heated at high temperatures in order to melt the aluminum.

Once they have been melted, the aluminium that is derived from the heating process is rolled out to a thickness of between 2.5 mm and 6 mm. afterwards, aluminium is ready for new use in form of recycled cans. The final step is the distribution of recycled products in various brands. According to the picture, in the United Kingdom, 74% of drink containers are recycled.

Recycling of Aluminum Cans IELTS Academic Writing Task 1

The diagram illustrates the steps involved in how aluminium drinks cans are recycled. Overall there are six stages in the process, from the cans being sorted at the collection centre to the melting down process at the recycling plant where new aluminium is formed, and finally where new cans are produced and ready for sale again.

To begin with, in the collection centre used drinks cans are put into a recycling bin and then separated into aluminium and steel. Following this, the sorted cans are transported to a recycling facility where they are crushed into cubes ready for melting down. Regarding the recycling process, the cubes of old aluminium are melted down at high temperatures and turned into bars of new aluminium.

As soon as these bars have been created, they are formed into thin sheets and rolled up. Subsequently, this rolled up aluminium is used to create new drinks cans. Once they are made, they are ready to be filled with beverages and distributed to vending machines for consumption. After that, the whole process is repeated all over again. ieltsx press

Also Check: The Maps Show a Road System as It is Now IELTS Map